Zortrax Reveals M300 3D printer in Amsterdam

Posted by Jacqui Adams on

Taken from 3D Printing Industry.

By Lydia Mahon

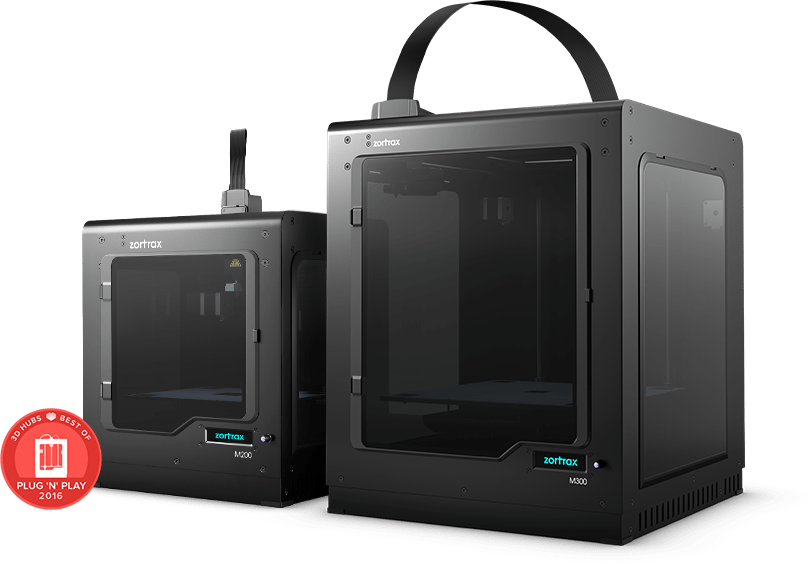

Zortrax, manufacturer of the award-winning M200 3D printer, is unveiling its latest device at the Additive Manufacturing Europe 2016 expo.

“The Zortrax M300 is our direct response to the needs of our customers. They’ve often indicated the need for a device that is as accurate and reliable as our previous M200 3D printer, but which would allow them to create larger, professional prototypes as a whole – without the necessity of splitting up a project into a series of smaller components”- says Rafał Tomasiak, founder and CEO of Zortrax. “The M300 is yet another step taken towards simplifying 3D printing for our end users. Eliminating the process of having to connect smaller prototype components makes the entirety of a project less engaging and time-consuming for our customers”- he added.

The M300 relies on LPD (layer plastic deposition) printing technology, which consists of applying layer after layer of 3D printing materials that have been melted at high temperatures. The M300 is capable of operating at a resolution between 90 to 300 microns from each single extruder. The 3D printer’s workspace measures 300x300x300 mm, whereas its external dimensions are 490x490x560 mm, users can also connect with the M300 using SD cards. The Zortrax M300 is capable of using 4 different types of 3D printing materials:

- Z-ULTRAT – a versatile material which allows users to create prototypes with characteristics similar to those created using injection molding techniques;

- Z-HIPS – a material specially designed for printing out larger models with a regular structure. This material’s matte finish is said to guarantee a smooth, uniform surface;

- Z-GLASS – a semi-transparent material designed for prototyping products which are meant to be produced using glass or transparent plastic;

- Z-PETG – a material that is resistant to all kinds of salts, acids and alkalis. This material allows for the creation of resistant mechanical prototypes which may become exposed to the adverse effects of such chemicals. Another characteristic of this material is its sturdiness and high physical resistance.

Zortrax’s latest device is based on the same design features as the smaller M200 3D printer, but includes several improvements. The new 3D printing material spools are larger than those used in the M200 and allow users to check how much material has been used; making it easier to plan each print and project. The M300 also comes with Side Covers. These protect a user’s 3D print and helps maintain a constant temperature within the build space, which can help prevent any model deformations.

The M300 3D printer will soon become available for purchase across 50 markets worldwide. Zortrax’s stand at the Additive Manufacture Europe 2016 expo not only features the M300, they are also presenting their previously released 3D printers: the M200 and the Inventure, as well as their specialized 3D printing materials and signature Z-SUITE software. Zortrax is hoping to attract the attention of expo participants with large-scale 3D models – including that of a giant superhero. The exact address of their stand at the AME 2016 event is: Europaplein 22, 1078 GZ Amsterdam, Hall 4/5 RAI Amsterdam, stand number: 400.

Share this post

- Tags: 3d printing, Zortrax