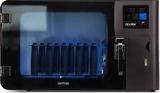

Zortrax Apoller Post-Processing Smart Vapor Smoothing Device

Zortrax's Post-Process Smoothing Device

Designed for Zortrax Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro and Z-HIPS 3D Filaments

The Zortrax Apoller is a desktop smart vapor smoothing device which gives your 3D printed object a clean, finished look. Every aspect of a smoothing process is managed by Zortrax's proprietary algorithms to get the looks of FDM 3D printed models on par with injection-molded prints.

How it works:

Step 1 Fill it up

The Apoller's solvent tank is filled with acetone or MEK, dependent on the kind of 3D filament the models you would like to smooth have been 3D printed with.

Step 2 Place models

Your printed 3D items are placed inside the Apoller's cabinet, 2-3 cm apart from each other. The Apoller door needs to be closed to start the process.

Step 3 Choose settings

The Apoller's touchscreen lets you select the type of filament the models used in the 3D and the solvent in the tank.

Step 4 Take models out

Once the smoothing process is complete, the models are taken out of the Apoller, and the smoothing process is done. No further steps are necessary.

The Apoller gives you the look of injection-molded parts

Zortrax Apoller can smooth models 3D printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro, and Z-HIPS, or their third-party equivalents. HIPS-based materials can be smoothed exclusively with MEK while acetone is recommended for Z-ASA. For all other supported filaments both acetone or MEK will work with the Apoller. The smoothing process leaves ASA-based materials with a mat finish. Other filaments come out with glossy surfaces. Vapors' circulation system guarantees that even intricately shaped models are smoothed uniformly. Zortrax Apoller also automatically dries the prints out which makes them ready to use shortly after taking them out of the smoothing chamber.

Key Operating Benefits!

| Device | |

| Build volume | 300 x 250 x 250 mm (11.8 x 9.8 x 9.8 in) |

| Connectivity | Wi-Fi, Ethernet, USB |

| Operating system | Android |

| Processor | Quad Core |

| Touchscreen | 4" IPS 800 x 480 |

|

Solvent compatibility

|

Aceton, MEK |

| Available materials | Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro, Z-HIPS |

| External materials | ABS, ASA, HIPS |

Weight and physical dimensions |

|

| Device (W x D x H) | 671 x 396 x 388 mm (26.4 x 15.6 x 15.3 in) |

| Internal dimensions | 340 x 270 x 260 mm (13.4 x 10.6 x 10.2 in) |

| Device weight | 30 kg (66 lb) |

| Process | |

| Maximum working temperature |

90° C (194° F)

|

| Minimum working temperature | -20° C (-4° F) |

| Minimum absolute working pressure | 0.4 bar |

| Ambient operation temperature | 15 – 30° C (59 – 86° F) |

| Storage temperature | 0 - 35° C (32 - 95° F) |

| Electrical | |

| AC input | 110 V ~ 13.6 A 50/60 Hz ; 240 V ~ 6.3 A 50/60 Hz |

| Power supply parameters | 24 V DC @ 14 A, 500 W |

| Maximum power consumption | 1500 W |

In the box |

| Device, Starter Kit |

We Also Recommend

QUESTIONS & ANSWERS

Ask a Question-

Will this machine smooth Nylons?

Hello. The manufacture reccommends that the following filaments can be used for the Zortrax Apoller Post-processing Smart vapor Smoothing Device. The device can smooth models 3D printed with Z-ABS, Z-ULTRAT, Z-ULTRAT Plus, Z-ASA Pro, and Z-HIPS, or their third-party equivalents.

-

Can this be used with more aggressive solvents; eg Cyclohexane?

No, the Apoller can only be use with Pure Acetone or pure MEK only.